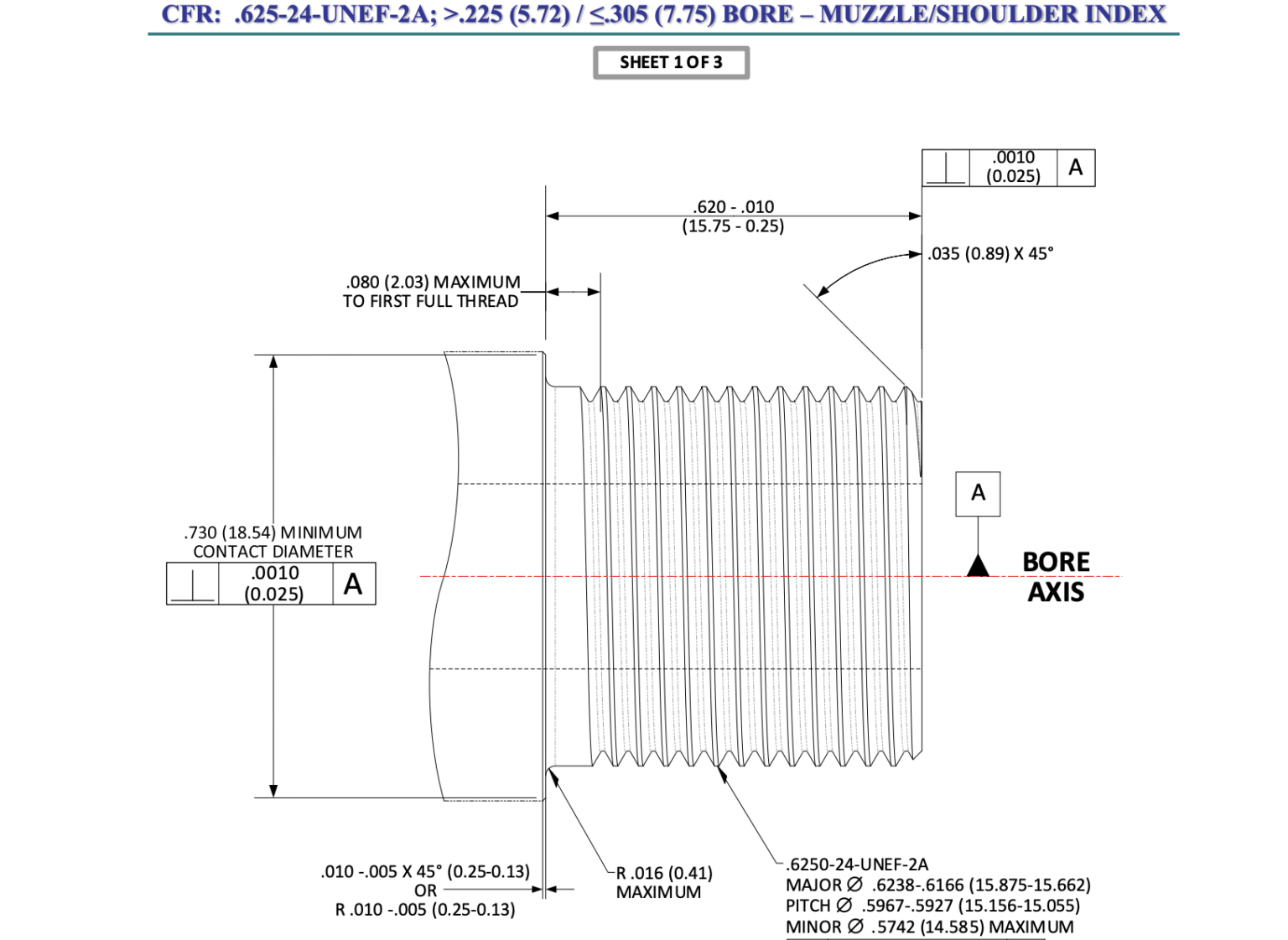

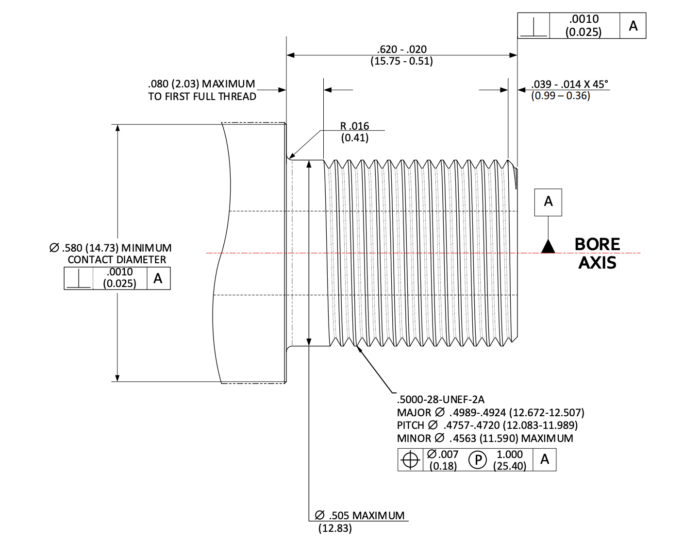

SAAMI, the Sporting Arms and Ammunition Manufacturers’ Institute, has existed since 1913 with standardization of cartridge and chamber dimensions (and cartridge maximum pressures) as its primary focus. With hundreds of ammunition manufacturers and hundreds of barrel manufacturers, it’s critically important that a shared standard exists for everyone to follow. Now, SAAMI has weighed in on a standard for barrel threads. You know, the threads at the muzzle onto which one screws a muzzle device like a brake, compensator, flash hider, or silencer.

As a firearm manufacturer myself (Black Collar Arms) and what you might call a “heavy user” of muzzle devices and suppressors over the last decade+, this was music to my ears. When we began making barrels at Black Collar, we had to decide on all of the specifications of the muzzle threads. There’s way more to it than just calling out 5/8×24 and hitting “go.”

How thick are the threads, what’s the pitch angle of the walls of the threads, how deep are the grooves, how tall are the tips, do the tips come to a sharp point or do you knock them down a little, how much threaded length is necessary from the muzzle to the shoulder, do you undercut in front of the shoulder, etc.? (yes, there are technical terms for each of these things that I’m not using here)

Ultimately it’s a balancing act. Thin threads with deep grooves and short tips will be compatible with the most muzzle devices from the most manufacturers, but the fit will be looser. Larger threads will result in a more precise fit, but may be too tight for accessories from some manufacturers to screw onto the barrel.

We consulted with experts, like the team at Silencer Shop who probably field more silencer and muzzle device compatibility questions than anyone else in the country. We searched for and requested technical drawings (or at least thread specs) from barrel and muzzle device manufacturers. Ultimately, we chose what we felt was as close to the industry norm as possible. What we felt was the best balance of compatibility and precision.

To be completely candid, the end result was pretty much an arbitrary choice. There’s a massive difference between 1/2×28 threads on the loose end of the spectrum vs. 1/2×28 threads on the tight end of the spectrum, but from both ends of the scale and everywhere in-between, it’s all 1/2×28 threads. Choosing some spot somewhere in the middle is . . . well, it’s just a choice. It’s an opinion.

While SAAMI makes it clear in the description that their specifications and drawings aren’t yet approved as the official, final standard, this is a huge step in the right direction for everyone making barrels and every sort of muzzle device.

I’d highly encourage all manufacturers to review these technical drawings and consider cutting their threads to these specs.

Good on SAAMI for recognizing the importance of setting and maintaining a standardization system for this critical component of a firearm, and for taking a major step toward setting that standard.

Read the full article here