I never used to be a knife guy, but at some point in my early 30s, I somehow started collecting whole gaggles of them. Although most of these are impulse buys or gifts, I’ve had the rare opportunity to see and test a few blades that really change the way I look at EDC blades as a whole.

Today, we’ll be taking a look at a blade from a somewhat unlikely source: Work Sharp. Although Work Sharp is historically a blade-sharpening tool company, they’ve just very recently released the first set in what I hope will be an entire family of blades with the introduction of the RMX series.

Below, we’ll be looking at my favorite of the bunch, and the one I’ve been carrying for the last few months, the Work Sharp RMX Compact Drop-Point, a blade with a very unique convertible pivot that lets you switch between a more traditional manually operated pivot, or an automatic pivot activated by a push button.

Sleek, Lightweight, and Rugged by Design

Although I wouldn’t consider the blade cheap, it’s certainly inexpensive for the materials, construction, and features the tiny knife offers.

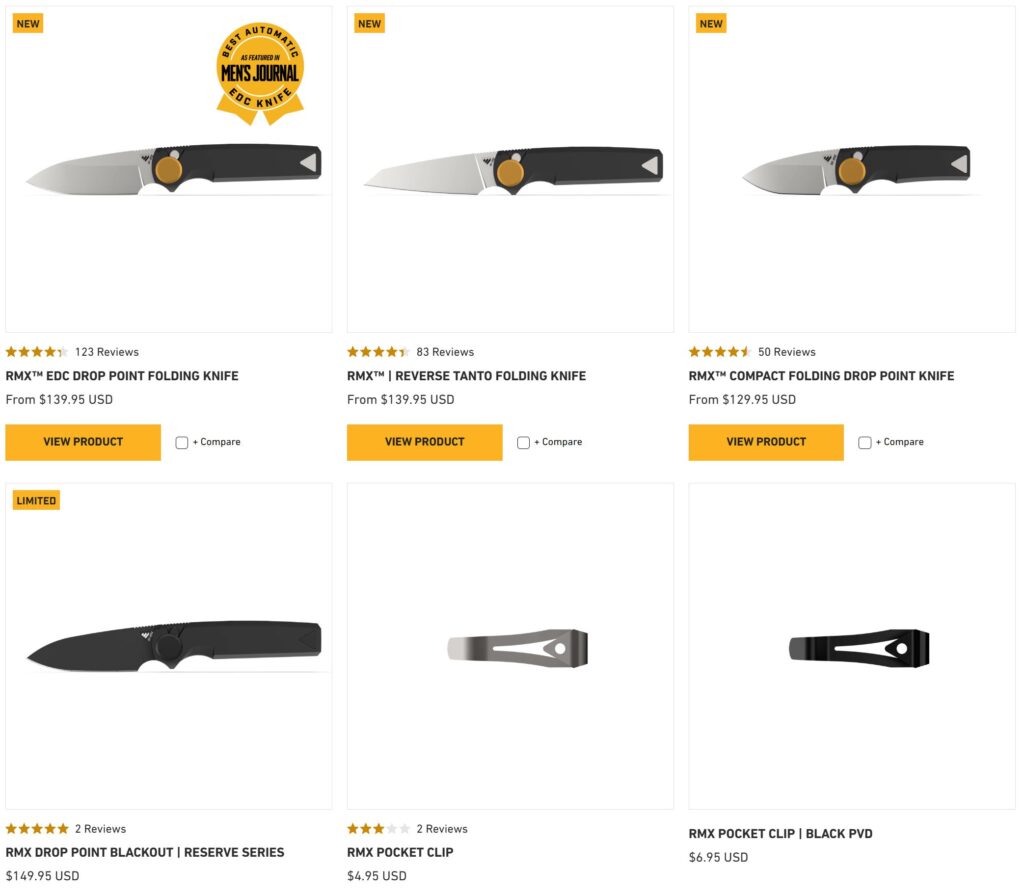

Coming in at an online price of just $$129.95, the compact version is the least expensive of the four currently available models, but the other 3 offerings are only $10 or $20 more and simply offer a different blade profile or a larger overall blade size.

There is also the “Reserve Series” that rounds out the top end of the price spectrum at $149.95

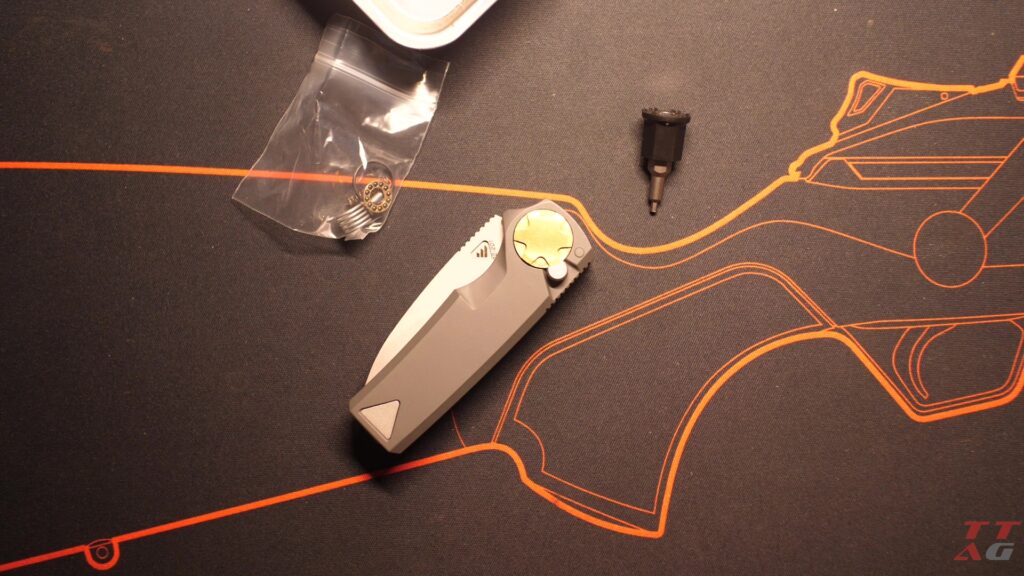

The RMX Compact and the rest of the Work Sharp RMX lineup come standard with the convertible pivot feature, along with all the included tools and parts needed for the conversion. Beyond that, the Compact version of the knife has an overall open length of 5.8 inches, with 2.4 inches of that being the blade length; not very big.

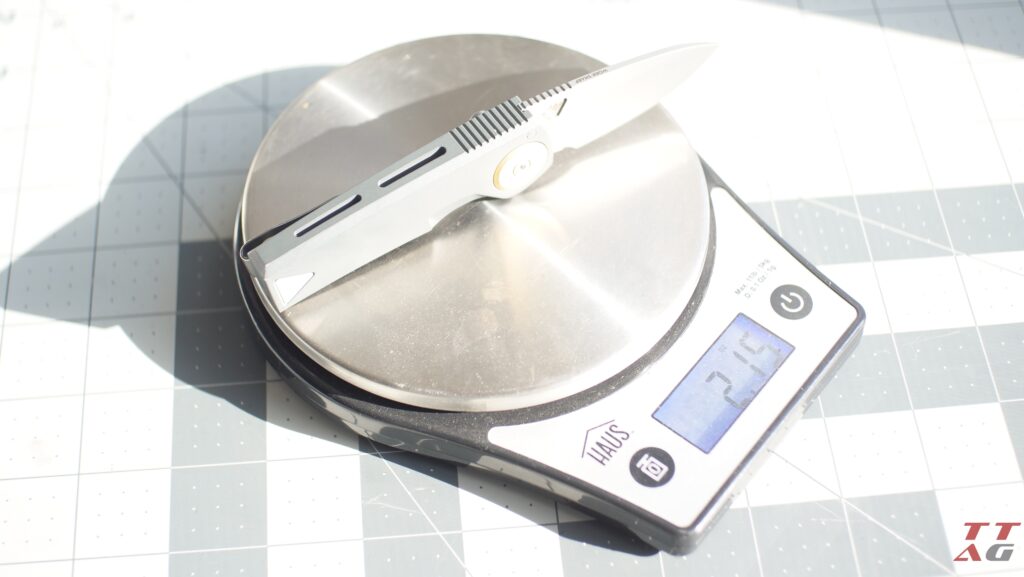

The closed RMX Compact measures just 3.4 inches long and about half an inch wide, including the pocket clip. Finally, the RMX Compact is virtually weightless, coming in at an officially listed weight of 2.24 ounces. However, my scale reads it as a touch lighter, with the automatic pivot set to 2.15 ounces.

I am a closet fan of tanto blades, but since the compactness of the RMX compact was the main draw for me, I went with the more versatile drop-point blade option, which is currently the only style offered for the compact version of the knife.

The larger models allow you to have a tanto-style blade. The included tip-up deep-carry pocket clip is reversible for the side you want it on and is available as a spare part on the Work Sharp website for less than $10.

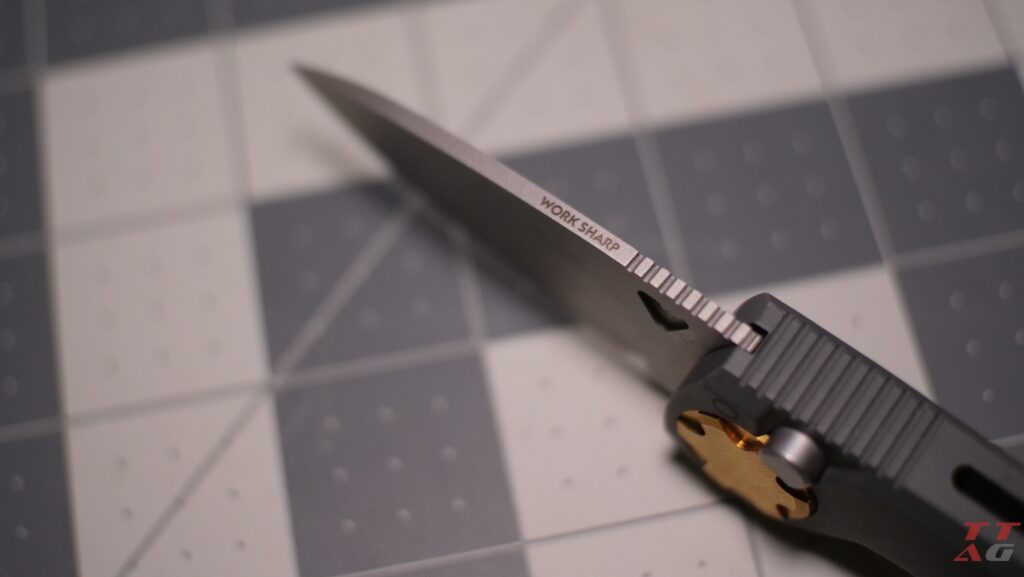

For styling, the M390 blade has a nice satin finish with small laser-engraved markings on it, while the magnesium body of the RMX series comes in either a black or Grey Cerakote finish.

Both are high-quality materials with the light magnesium alloy body helping keep the entire package lightweight, and the M390 super steel giving you a solid blade steel in a reliable profile.

The Convertible Pivot System

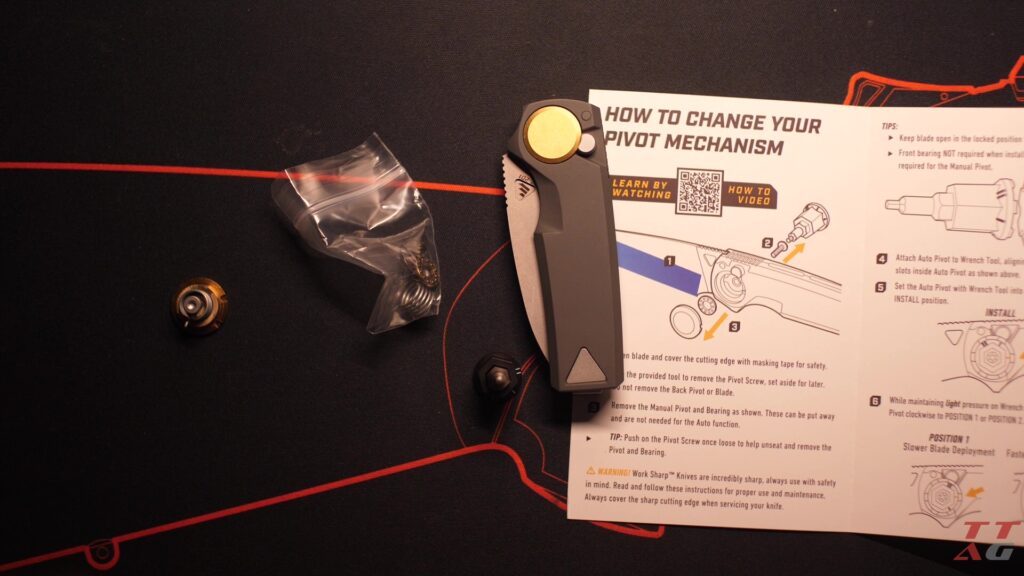

I’ve only recently had the opportunity to take apart and assemble some of my own manual and automatic knives. After having successfully done this for both Benchmade and even Microtech knives, I was honestly quite skeptical of the ability of the average knife owner (me) to easily swap out from a manual pivot to an auto-pivot system in just a few minutes. However, the genius of the RMX series’s convertible system is in just how simple it is.

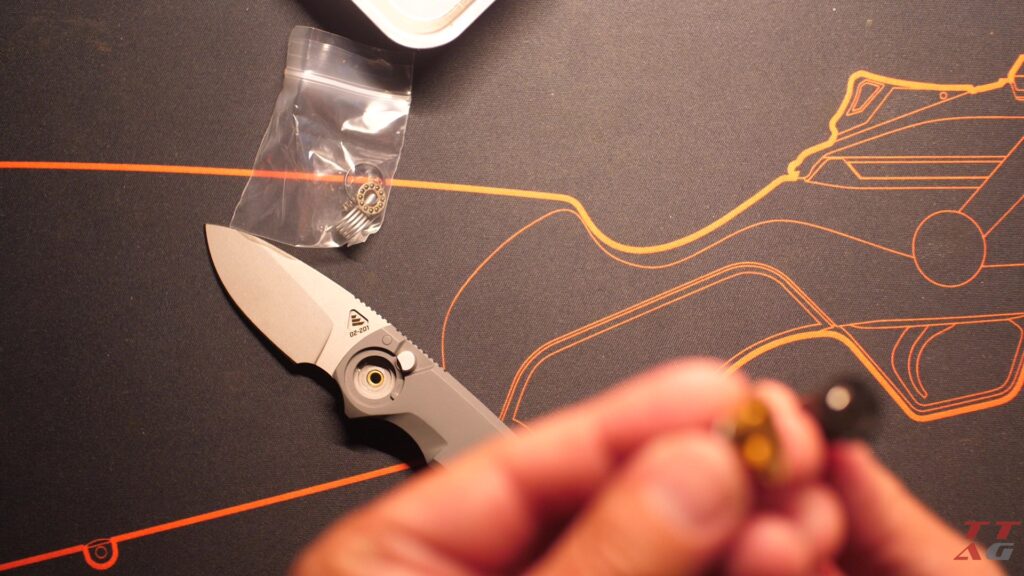

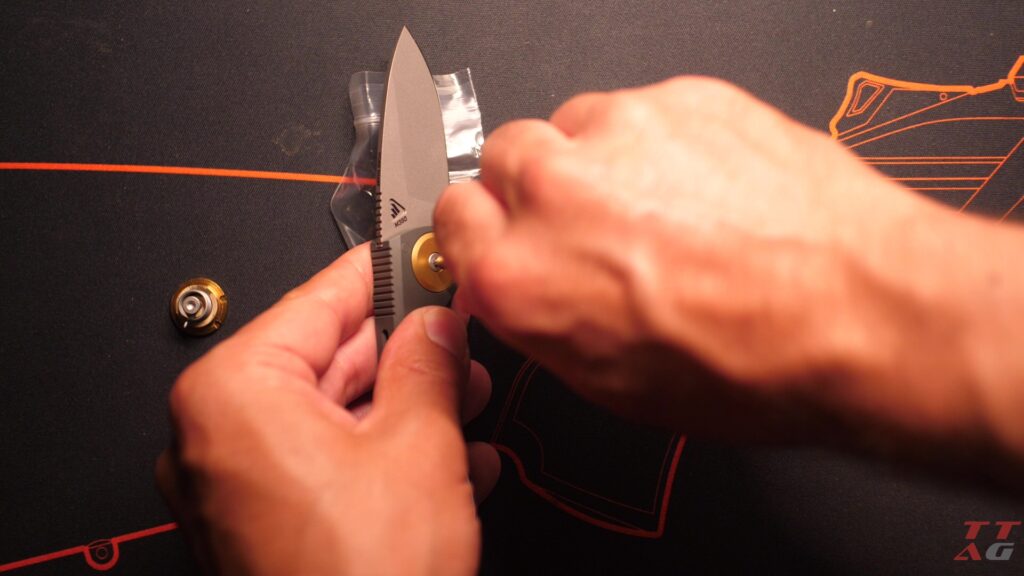

The knife ships with a manual pivot mechanism installed. Along with the knife, you receive an automatic pivot cartridge packed with a torsion spring, plus a specialized wrench tool (a 2mm hex) and a magnetic key to assist installation and removal.

Nice, high-detail instructions and illustrations are also included for all of you visual learners out there, and Work Sharp also had Kyle and the rest of the team put together a nice video on how the process should be done if you want to make 100% sure you’re doing it right.

Having done this a handful of times myself, the process is actually super simple, and it’s quite the innovative feature and one that might help people who maybe have a change of preference, or will be having some extended time in a state where automatic knives are phrohibited, and want to doubly make sure they won’t get ticketed or have their knife confiscated becasue of local laws.

In the Pocket and Out in the Field

I’ve been carrying the RMX Compact since the very end of summer, and so far it has become part of my permanent carry rotation – especially when pocket space is limited or I’m not wearing a belt. Even beyond the unique pivot system, the biggest feature that the RMX Compact offers is its overall lack of weight and its space-efficient size.

There have been more than a handful of times when I’ve accidentally carried around two knives. On numerous occasions, I forgot I had pocketed the RMX Compact, and accidentally left it to go through the washing machine because I’ve forgotten it’s clipped to my pocket – it’s that light. The deep carry clip’s design means that the body of the blade sits below the top of your pocket, leaving only the clip visible.

Part of the reason I’ve taken a liking to the blade so quickly is also due to its overall functionality. The overall blade design and material are very good, but by no means perfect in my mind. When it comes to overall durability, the M390 blade is one of the best materials, I think you can use for an EDC blade.

Combined with the blade thickness and overall breadth, the M390 stands up great against everyday cutting tasks as well as some light abuse. M390 is notoriously labor-intensive to re-sharpen and hone, so either investing in a good Work Sharp tool sharpener is a must, or get used to spending a lot of time sharpening the RMX Compact if you’re the type who actually uses their EDC blades for everything.

Two small things rub me a little bit the wrong way when it comes to the overall implementation of the RMX Compact Drop-Point edition. First off, the blade features great lockup and stability overall, with the manual pivot hardware having zero side-to-side play in the blade.

Once you swap out pivot cartridges, the auto-pivot tends to have a tiny bit of play, just enough to be annoying if you notice it. However, despite the amount of blade play, I’ve tried to collapse the locking mechanism with some hard hits and putting a decent amount of pressure on the top of the blade, and the lock has held up beautifully.

Secondly, and only slightly less important, is the overall blade profile. Everything is perfect up until the heel of the blade. The RMX blade features what is called a “plunge choil,” which basically translates to a recessed cut in the actual blade that allows you to have a finger in there for more blade control without cutting your finger.

Although this is great when you’re using it, it’s quite annoying when you’re trying to make long cuts through a material and the heel of the blade is completely unsharpened, meaning you’re more liable to get caught up in the material instead of cutting through it. This is something that I’ve had to adapt to with practice, but it still gets in the way from time to time. The choil, however, does its job and allows you to sharpen the full length of the blade easily.

Imperfect, But Too Good to Pass Up

There’s still probably more to say about the RMX Compact and the rest of the RMX lineup from Work Sharp Tools. Their first step into the blade world was somewhat unexpected to me, but in retrospect, it turned out to be a great new avenue for the company.

M390 is a great blade steel, and even though it’s often associated with knives that often go for $250 or more, it’s nice to see a more budget-friendly option, especially when combined with the convertible pivot cartridges, tools, and the magnesium alloy body. Overall, I’d say the knife isn’t perfect. The RMX Compact has some design features that I, as the end user, would like changed. However, what wins me over in the end is its combination of price, construction material, and features that make it too good to pass up.

For $130, you really can’t do much better in my opinion. I typically don’t make hard recommendations for buying gear, but this is one I can safely recommend if you’re a knife guy or are just looking for something to upgrade from a truck stop knife to something truly refined from the good people over at Work Sharp Tools.

More Knife content from TTAG:

Read the full article here